Precision Feeding Management System for Ranch BM-JZSW

The TMR precision feeding system can monitor the execution of ingredients, mixing, and spreading in real-time,reduce human error; accurate to the feed situation of the livestock house, so that the feeding is more accurate and the nutrition is more balanced.

We're here to help: Easy ways to get the answers you need!

A. System Introduction

The TMR precision feeding system can monitor the execution of ingredients, mixing, and spreading in real-time,reduce human error; accurate to the feed situation of the livestock house, so that the feeding is more accurate and the nutrition is more balanced.Its main operations involve Cattle pen management, formula management, ingredient inquiry, and sprinkling inquiry.

B. System composition:

1. TMR mixer (including electronic scale)

2. Forage feeder (forklift)

3. Computers

4. Feeding formula weighing monitoring and analysis management software

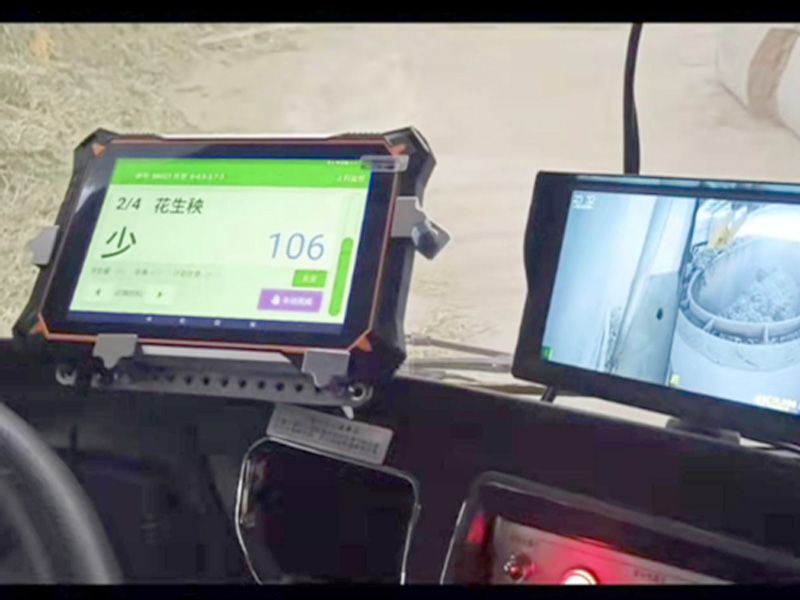

5. Spreader truck (including electronic scale)

6. Spillage Weighing monitoring software

C. System feature

(1) TMR precision feeding management system can monitor the whole process of full mixed ration preparation and feeding, display real-time operation information on site, and prompt the work progress of the operator; backend data records can be traced throughout the entire process.

(2) Improve the accuracy of feed preparation and feeding operation, achieve a high degree of unity of design formula, mixing formula and feeding formula, and achieve accurate implementation of nutrition design.To achieve high utilization of feed and minimize waste while meeting the nutritional needs of beef cattle.

(3) The feeding and scattering data, as well as the time and error of the operation process, will be transmitted to the system backend, which can trace the work situation of employees, calculate the work error situation of employees, and assess feed preparation personnel, TMR truck drivers, and forklift drivers.

(4) Both feed usage and dry matter intake of beef cattle can be statistically analyzed.

D. System Introduction

1. Cattle pen management

Add according to the actual situation of the ranch cowshed,The cattle group setting includes fields such as cattle house name, cattle house number, and number of cows. The cattle house name, cattle house type, and number of stocks can all be changed to calculate the feeding amount during the production of feeding plans.

Cattle house creation:

2. Recipe management

Create the recipe used by the ranch, enter the recipe name, recipe code and planned total, the weight of each feed and the order of feed addition, the order of feed in the recipe is the same as the LED screen displayed when the TMR plan is executed, and the recipe can be viewed, modified, copied and deleted (see Recipe modification for details).

E. System advantages

1. Intelligent and accurate diet preparation, precise execution of design formula, and highly consistent among the three formulations in the pasture. Minimum feed waste should be achieved on the premise of meeting the nutritional needs of cows;

2. Intelligent and precise feed feeding, the feed amount in the enclosure is highly consistent with the standard to avoid feeding waste and insufficient feeding;

3. Real-time prompt feed how much difference, so that the operator can understand the operation situation, to avoid adding errors;

4. Wireless communication, homework errors can be uploaded to the backend system at any time, and operational errors can be traced throughout the entire process;

5. Save labor costs, reduce intensity, save operator labor time, and improve operational accuracy;

6. High reliability, suitable for use in cold and humid areas。

Please send us your request and we will reply to you within 24 hours.

Reach out to us anytime and we'll happily answer your questions.

Tel

+8613253500563Livestock Weigh Crate, with Reader, antenna and electronic weigh scales, will automatically identify the animal and accurately record its weight. This Livestock Scales can automatic identification, weighing and recording for faster, more precise record keeping.

Our chute is the most simple and easy to use chute on the market. Our chutes are perfect for all cattle operations that want added convenience. It turns out that this slide can cut working time in half!

And the safety of the operator can be well guaranteed.

The beef cattle feed intake measurement column system includes electronic scale, feeding trough, gate, electronic ear tag reader, industrial touch screen computer, electronic ear tag information collection statistical management software.